How Does a Mechanical Watch Work?

May 15, 2016The mechanical watch does what any watch does—it measures time. It does this with the help of a mainspring that requires winding periodically. Winding the watch mobilizes a series of gears to power it, setting off that comforting tick of a working watch.

Of course, the inner workings of a mechanical watch are more complicated than just winding a gear. To unlock the secrets to the inner mechanisms, let’s dive deeper into learning how a mechanical watch works.

Core Mechanisms

While different watchmakers will add their touches of ingenuity, all mechanical watches have the same core mechanisms.

Mainspring

As mentioned, an essential piece of a mechanical watch is the mainspring. This integral asset connects to the winding pinion in the center and the mainspring barrel on the outside. The two move independently.

The winding force is pushed through the pinion, causing a click to keep the spring in place. The spring power transmits through the barrel rotation.

Wheel Train

Next to the mainspring is the wheel train, a set of interlocking gears that permit the timekeeping hands and wheels driven.

The center wheel drives directly at the force of the mainspring barrel, rotating completely once every hour. It is how the minute hand works.

A third wheel adjoins the center wheel to the fourth wheel, causing a rotation once per minute and powering the second hand. Each gear connects to a central axle with a synthetic jewel bearing to reduce friction and wear.

Escapement

Located at the wheel train’s end is the escapement, providing the most delicate part of the watch. This piece controls the power flow from the mainspring and prevents it from releasing its power all at once.

The escapement is easily visible with most mechanical wristwatches and easy to spot as a moving component. Whenever the pallet fork switches to lock the escape wheel, you hear a tell-tale click. The frequency determines how many times the second hand moves per second.

The escapement also utilizes jewels to reduce wear and tear, as well as a shock-absorbent piece. This mechanism prevents gears from being thrown out of place by an unexpected impact.

Balance Wheel

Within the escapement is the balance wheel. It combines with the hairspring to oscillate back and forth to click the pallet fork into place.

The force transferred from the mainspring to the escape wheel pushes the pallet fork to flick the balance wheel. A hairspring checks the balance wheel rotation, allowing the wheel to oscillate back towards the pallet fork.

When the balance wheel returns, it clicks the pallet fork to a second position and releases the escape wheel for just a second. This process restricts the escape wheel to just a short movement window and prevents gears from spinning freely. All of this occurs in a fraction of a second.

Time Setting & Winding

A distinguishing factor between battery-operated and mechanical watches is the need to wind the watch now and then. To do this, you utilize the crown, motion works, and supporting structure.

Crown Assembly

The crown is an exterior piece that allows contact between the wearer and the watch’s inner workings. This grooved exterior piece is connected to the winding stem and can adjust to varying lengths for different settings.

The adjustment allows you to click the setting lever on different features on the setting jumper. Ultimately, the crown allows you to tighten the mainspring and allow the inner workings to be powered smoothly.

Motion Works

Right next to the center wheel is a special gear set providing functionality. The motion works gears permit the watch hands to rotate to the desired time setting.

It also performs a speed reduction ratio of 12:1 for the hour hand, which ensures the hour hand runs twelve times slower than the minute hand. These special gears are the minute wheel, hour wheel, and cannon pinion.

Supporting Structure

The supporting structure consists of different metal plates specially shaped to hold the various components in place.

The ‘main’ plate is the largest and provides a base. The second-largest, the ‘barrel bridge,’ keeps the mainspring and nearby pieces in place. Other smaller pieces, like the ‘wheel bridge’ and ‘pallet bridge,’ support different structures in the watch.

Frequently Asked Questions

How Long Do Mechanical Watches Last?

Mechanical watches are the height of durability. With jewels to reduce inner friction and no hard drops, you have a watch for a lifetime on your hands.

There’s a reason mechanical watches are often treasured family heirlooms. Even damaged watches you can repair to extend their longevity.

Family-owned businesses like Precision Watches are well-versed in the inner workings of mechanical watches. With the correct replacement parts on hand, we can restore watches to working order.

Is It Ok to Let a Mechanical Watch Stop?

If you’ve dug up a lost watch, you may question if winding it is worth it. Mechanical watches do stop if not correctly wound. Most of the time, winding it will be sufficient to get it back up and running.

While we don’t recommend letting your mechanical watch stop, it is not the worst thing you can do to your watch.

Some newer models of mechanical watches even come with a power reserve indicator, giving you an idea of just how much power is on hand and when it needs rewinding.

Conclusion

While digital watches and smartwatches are growing in popularity, mechanical watches remain a timeless choice. Mechanical watches can be a status symbol, heirloom, or personal timepiece. Regardless, understanding the inner workings permits you to know what makes your watch tick.

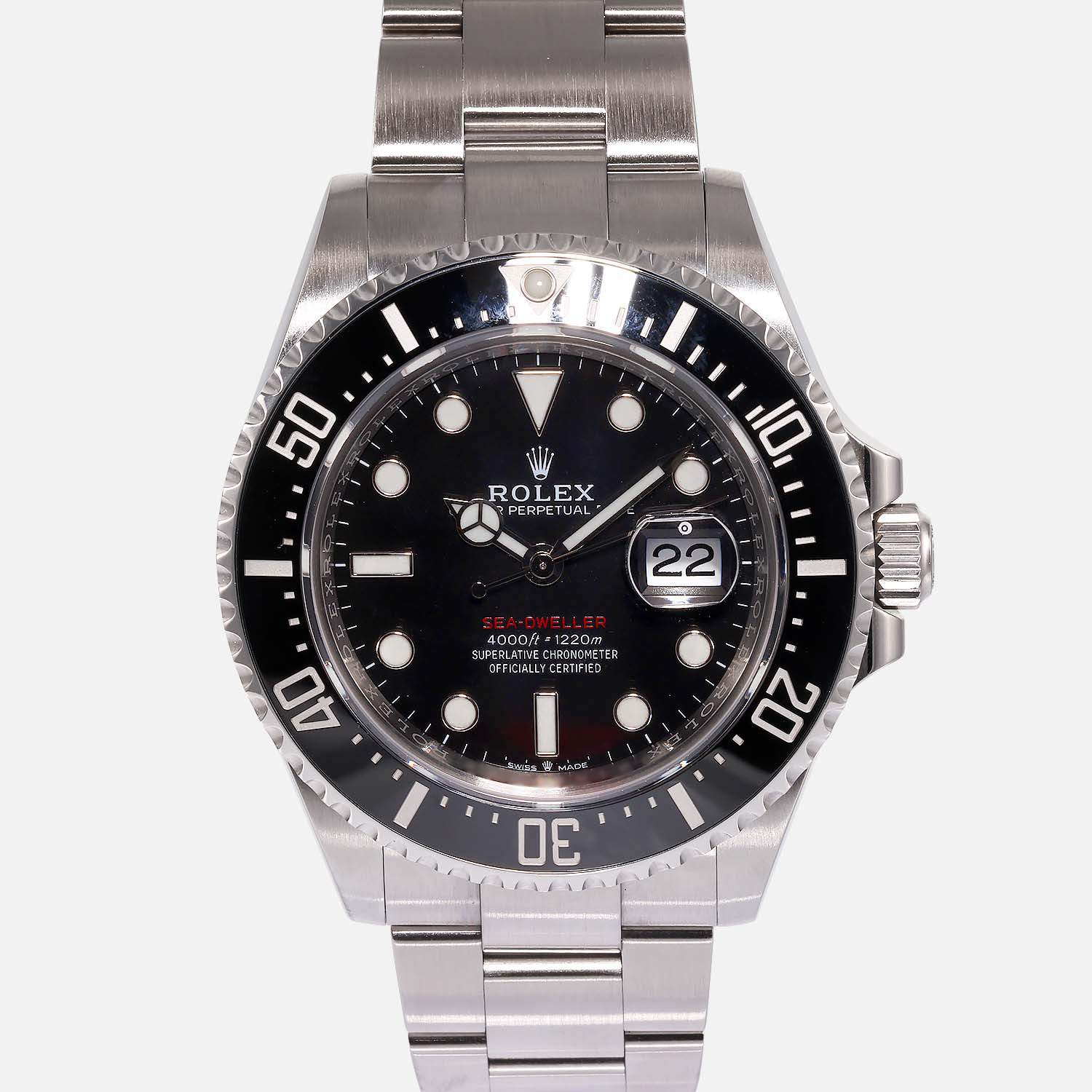

All of Our Watches Are 100% Authentic and Certified By Our In-House Swiss Trained Watchmakers

Brick and Mortar Store For Over 30 Years

Have Any Questions? Speak With One Of Our Sales Professionals